Discover How CCR Helps Analyze 800 wells in Just 8 Minutes!

Ambyint’s Cognitive Card Recognition (CCR) technology automates rod lift dynacard inspection with up to 95% accuracy, delivering real-time insights into surface and downhole challenges.

By detecting anomalies like hole in tubing, rod parts, standing valve leaks, and worn pumps (and many more!), CCR enables teams to proactively manage wells, reduce downtime, and boost production efficiency—all powered by AI that never sleeps.

Download the Whitepaper Now

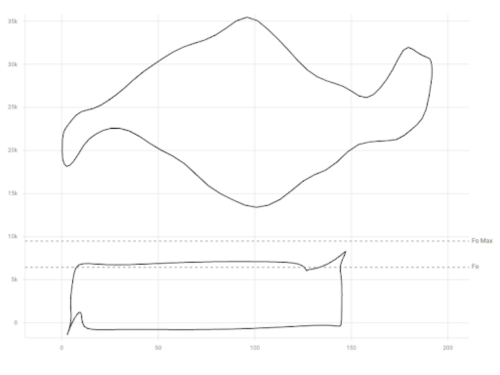

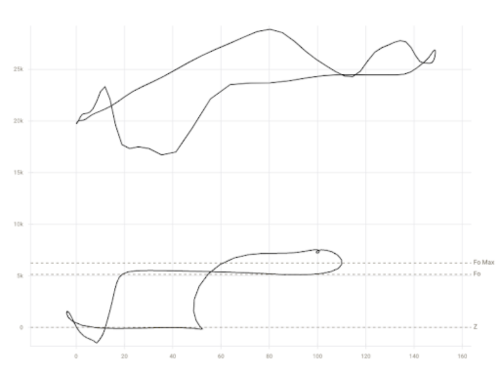

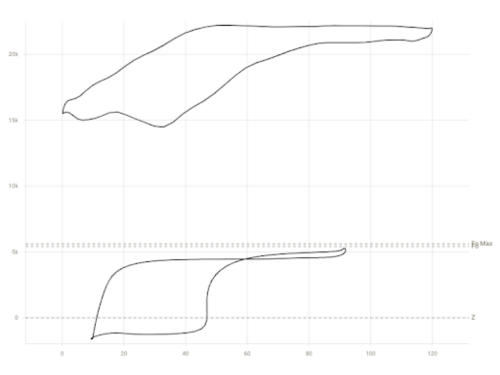

Can You Spot the Anomalies?

Test your dynacard expertise with our anomaly detection quiz! Examine real-world dynacards and challenge yourself to identify issues like hole in tubing, rod parts, standing valve leaks, worn pumps, and more.

Achieving Operational Excellence with AI-Powered Insights

Managing unstructured data and ensuring equipment reliability are major challenges in rod lift operations. Ambyint’s Cognitive Card Recognition (CCR) technology helps engineers overcome these obstacles with precision and actionable insights.

Automate Anomaly Detection

Identify surface and downhole issues with up to 95% accuracy. Detect anomalies like hole in tubing, rod parts, standing valve leaks, worn pumps, and more, enabling proactive solutions to prevent costly failures.

Reduce Downtime and Maximize Production

Move from reactive to proactive operations with real-time insights. Minimize well downtime, deferred production, and maintenance cycle times while maintaining optimal performance.

Optimize Workflows

Eliminate time-consuming manual tasks with automated dynacard inspection and classification.

Improve Equipment Reliability and Lifespan

Address anomalies early to extend the life of critical equipment. Optimize performance, reduce unnecessary wear, and lower operational costs with data-driven maintenance.