The InfinityRL™ improves operations in the oil and gas industry by automating setpoint management, real-time surveillance, and anomaly detection. This enables teams to concentrate on the most critical wells, reducing inefficiencies and downtime. With our comprehensive analytics dashboard, you gain a clear overview of field production, enhancing both well performance and workforce efficiency.

Ambyint’s CCR helped analyze 800 wells in just 8 minutes!

.png?width=409&height=266&name=rod-lift%20(1).png)

Ambyint Rod Lift FAQs

What types of POCs do you operate on?

- Lufkin 1.0

- Lufkin 2.0

- Smarten

- Weatherford-RPOC

What are your SCADA requirements?

- Agnostic

What data requirements do you have?

Well Data

- Well Header

- Control System

- Downhole Equipment

- Wellbore Information

- Reservoir Information

Time Series Data

- SPM

- Fillage

- Fluid Load

- Min Load

- Peak Load

What surveillance and analytics do you offer?

- Well Specific Analysis Page

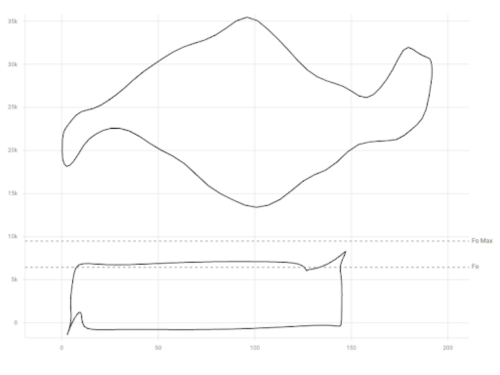

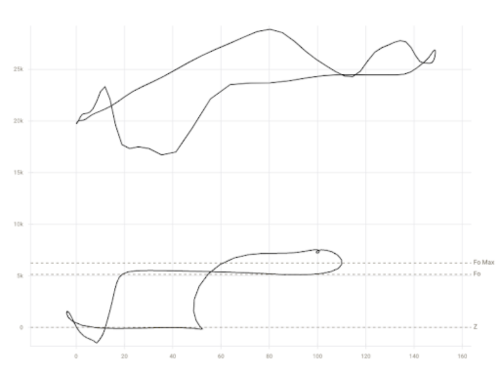

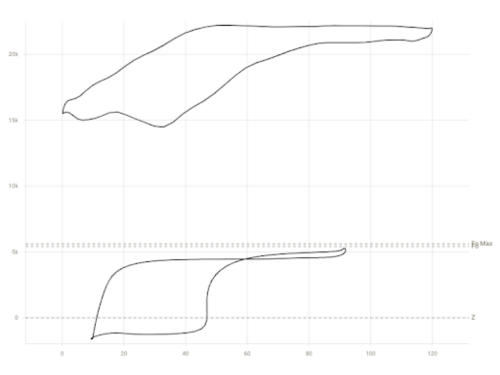

- Dynacard viewer

- Daily Operations Dashboard

- Well Review Dashboards

- Automated Email Reports:

- Daily Operations Reports

- Weekly Monthly, Quarterly Management Reports

What types of anomalies do you monitor for?

- Deep Rod Part

- Delayed Traveling Valve

- Hole in Barrel

- Hole in Tubing

- Plunger Undertravel

- Stuck Pump

- SV Stuck Open

- Worn Pump

- Fluid Pound

- Gas Interference

- Bad Data

- Card Distortion

What setpoints do you help manage?

- SPM

- Idle Time

What HRAC edge devices do you support?

- Wifi – 288 cards/day

- LTE – 96 cards/day

- SAT – 24 cards/day

Boost Productivity

By allowing workforces to focus on the rod lift wells that need the most attention while leaving the rest on cruise control, our solution decreases the labor hours required for operations.

Anomaly Detection and Predictive Maintenance

Automated dynacard-based anomaly detection helps workforces quickly identify issues that might require field work, ultimately leading to decreased downtime.

Autonomous Setpoint Management

Autonomous setpoint optimization allows for immediate adjustments to rod lift well operations, resulting in reduced inefficiencies, downtime, and a production increase of 1-5%.

Surveillance and Analytics

With the analytics dashboard and automated reports, managers can gain a comprehensive view of rod lift well operations, optimizing both production and workforce efficiency.

Optimizing Your Production – Here’s How

InfinityRL™ features autonomous setpoint optimization and automated anomaly detection powered by a proprietary horizontal well physics engine. The data generated by the system is made available through an analytics dashboard as well as automated reports.